Tough Gear. Bloody Good Prawns: Gold Coast Marine Aquaculture backs SPITWATER for the dirtiest jobs

When you’re running a prawn farm on the banks of the Logan River, everything — and we mean everything, gets pushed to its limits. Just ask Shannon Moore, General Manager of Gold Coast Marine Aquaculture (GCMA) and second-generation prawn farmer.

“We’ve got some of the toughest stuff to clean you’ll find anywhere. And we need products that are just as tough. That’s why we use SPITWATER,” Shannon says.

More than a fish tank

Spread over 150 hectares, GCMA is home to 50 one-hectare ponds, 20 million prawns per season, and a full on-site operation, from hatchery to harvest through to processing.

“People think we’re working in tanks,” Shannon says. “But our prawns grow in open-air ponds, each one the size of a footy field.”

Over four months, baby prawns barely a centimetre long are grown to full size, harvested, processed and shipped across Australia. At Christmas, locals can even grab them straight from the farm gate.

.png?width=1080&height=1080&name=Gold%20Coast%20Tiger%20Prawns-farm-1000x1000%20(1).png)

Quality first

GCMA isn’t the biggest farm in Australia, but they are one of the most awarded — including Champion Prawn at the 2023 Sydney Royal Easter Show.

“Our focus is on quality,” Shannon says. “We can’t grow the volume some of our competitors do, so we make sure we grow the best.”

It’s a 24/7 operation. Prawns are fed four times a day, even at 10pm and 4am. And when the season ends, the real grind begins.

Off-season hard yakka

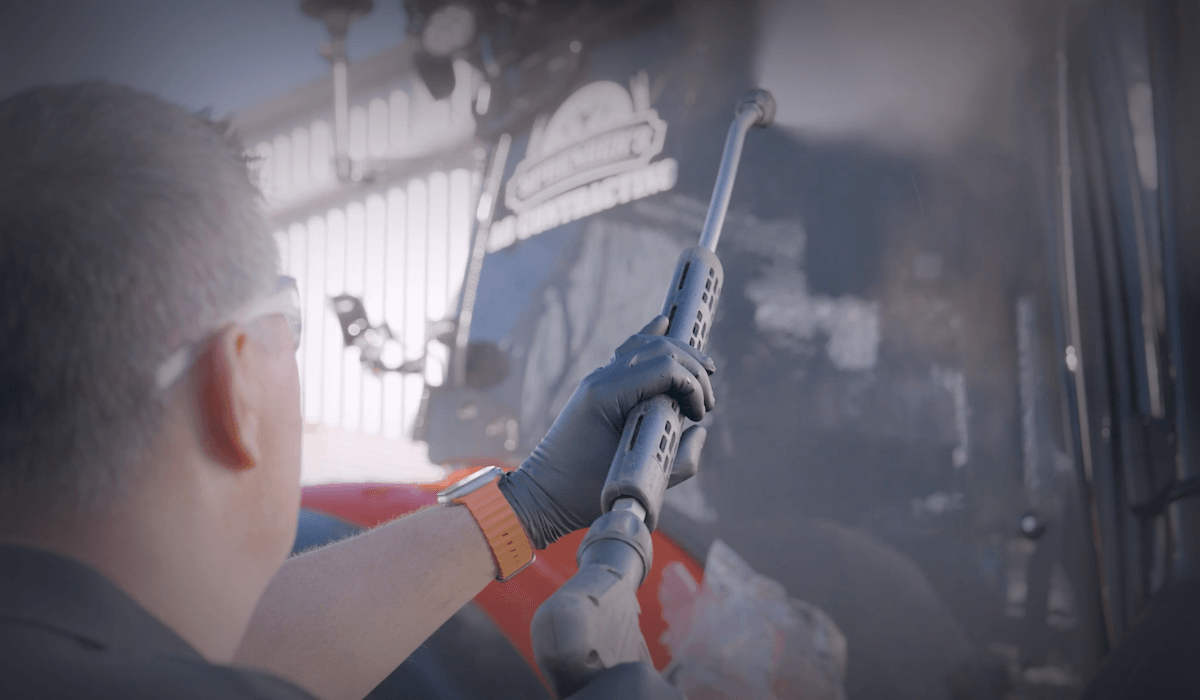

“That’s when the SPITWATERs come out,” Shannon grins. “We’ve got 600 aerators, 50 ponds, and 20 kilometres of bank to clean. Everything’s covered in salt, slime and barnacles. It’s brutal.”

Aerators, monks, inlets, and bank liners all get pressure cleaned. Paddlewheels are pulled in with cranes, barnacles blasted off for hours at a time.

“We call it the Sydney Harbour Bridge job. By the time you finish, it’s time to start again,” Shannon says. “It’s hard, physical work. Ten hours a day with barnacles in your face and salt in the air.”

Built to last in a hostile environment

GCMA’s saltwater environment is unforgiving. Equipment needs to work when it’s called on. No excuses.

“We’ve got one SPITWATER in our stable that is over 10 years old,” Shannon says. “They sit for a bit, then run flat-out. And every time we fire one up, it’s ready to go.”

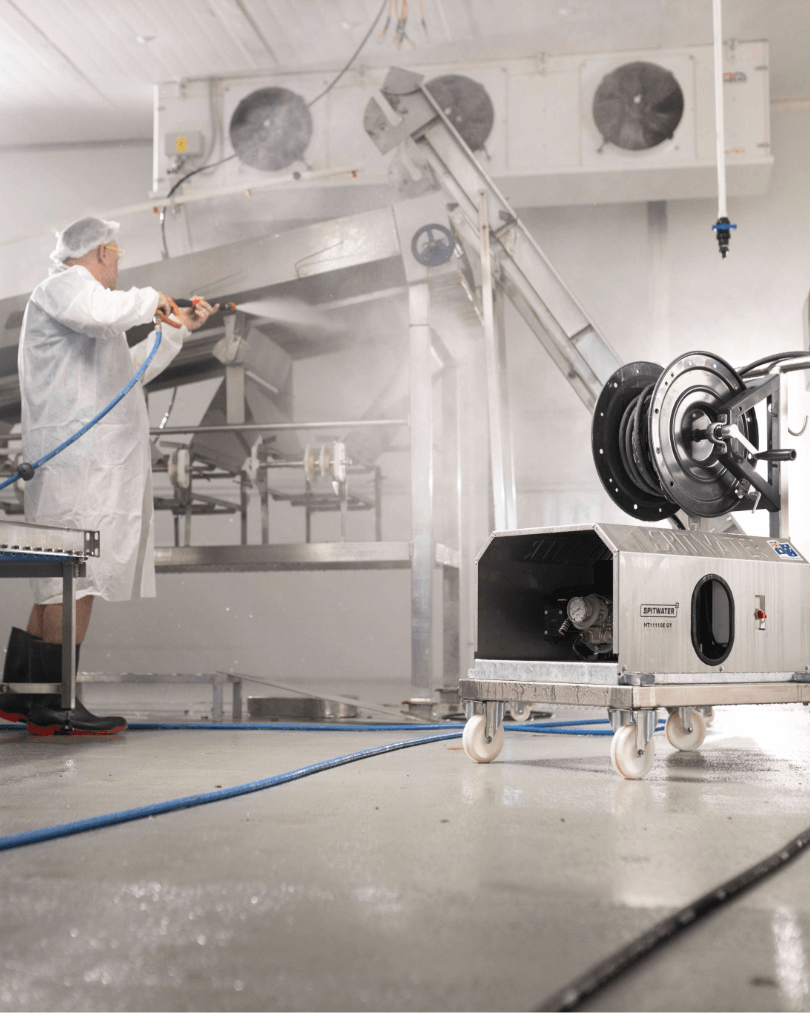

Inside the processing plant, it’s the same story. Stainless steel gear, saltwater pumps, and food-safe foam systems keep the facility spotless.

“We clean before, during, and after every shift. That’s hours a day just on cleaning, and it has to be pristine for food safety.”

Why SPITWATER?

For Shannon, it’s about more than the machines.

“SPITWATER took the time to understand what we need. They didn’t just drop off a unit and disappear. They’re a local, family-owned company that stands by their gear. That matters to us.”

Whether it’s blasting barnacles off a paddlewheel or sanitising a processing line, GCMA knows the job isn’t done until it’s done right. “We’re cleaning some of the toughest stuff you’ll find on a farm, and that’s why we choose SPITWATER.”

Want to see how SPITWATER handles the toughest cleaning challenges?

Book a demo or find your local dealer today.

Comments