On the farm, every day brings a new cleaning job. Machinery needs attention, livestock areas need washing, and equipment must be ready for work. Choosing the right pressure washer for the job saves hours and protects valuable gear.

From heavy washdowns in the workshop, sanitising sheds through to keeping machinery in peak condition, each task on the farm calls for a different type of cleaning power. By matching the right SPITWATER pressure cleaner to the job, you keep operations moving, equipment lasting longer and workdays more efficient.

Here are some of the most common cleaning jobs across agriculture and the key things to look for in a pressure cleaner to get them done right:

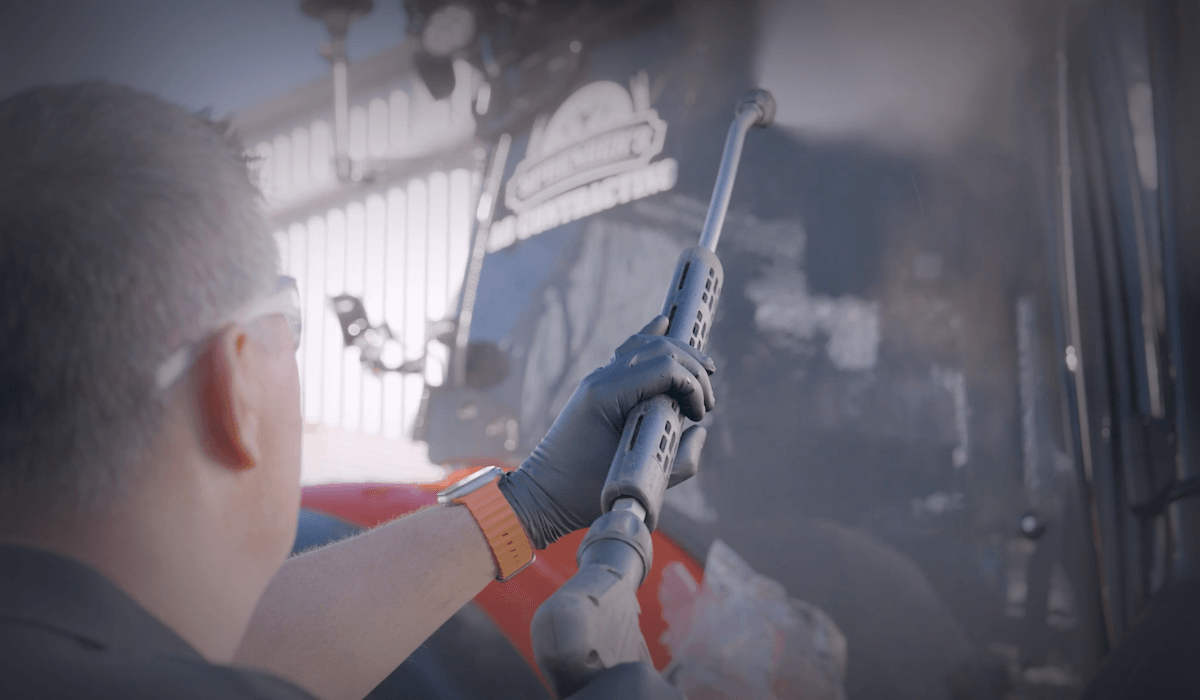

Machinery and Vehicle Washdowns

Harvesters, tractors and utes pick up heavy dirt, grease and grime. They need more than a rinse to stay in top condition.

- Best choice: Hot water pressure cleaners

- Why: Hot water cuts through grease and oil fast, reducing cleaning time

- Options: Medium duty for regular use or heavy duty for daily large-scale cleaning

Recommended:

Workshop and Wash Bay Cleaning

Farm workshops and wash bays demand reliable machines that can run often and handle the dirt of daily operations.

- Best choice: Cold water electric pressure cleaners with FlowRPM chemical solutions

- Why: Simple to operate, and designed for continuous use

- Options: Single phase for smaller wash bays and workshops, or three phase for heavier daily use and higher demand.

Recommended:

Remote or Out-of-Shed Cleaning

Sometimes the job is out the back paddock or at the far end of the property. Mains power isn’t always available.

- Best choice: Cold water petrol pressure cleaners

- Why: Easy to transport and operate anywhere on the farm to handle fences, sheds and equipment where power access is limited

- Options: Direct Drive for short, regular cleaning jobs, or Belt Drive for longer sessions and heavy-duty tasks

Recommended:

Livestock & Produce Areas

Where livestock are kept or produce is processed, hygiene is critical. Sanitisation saves time, supports compliance and protects animal health.

- Best choice: Hot water pressure washers paired with fogging nozzles and FlowRPM chemicals

- Why: Hot water and specialist chemicals provide a deeper clean and sanitisation

- Options: Heavy duty for larger farms or facilities, or medium duty with single phase power.

Recommended:

The Right Setup Saves Time and Effort.

SPITWATER accessories and FlowRPM chemicals turn one machine into a solution for many farm jobs.

- Foam cannons for increased contact time of chemicals on machinery

- Sludge pump for dewatering, turns your pressure cleaner into a transfer pump at 300L/m

- Drain nozzles can be used to help clear clogged drains

- Turbo lance for paint and mould removal without the need for chemicals

- Underbody cleaners for vehicles

- Extended lances for sheds and roofs

- FlowRPM chemcial solutions for faster results

Tailored SPITWATER Solutions in Action

For some operations, an off-the-shelf machine isn’t enough.

Poultry processing facilities, for example, face a mix of tough outdoor washdowns and strict indoor hygiene standards.

For one customer, SPITWATER designed a custom trailer solution powered by a SW21-200SDE diesel 3000 PSI, 21L/min hot water pressure cleaner - paired with an 800L water tank and dual hose reels for ultimate flexibility.

This setup gave the facility confidence that every area, from drains to processing rooms, could be cleaned quickly, safely and in line with compliance requirements.

Every job is easier with the right cleaning power

Don’t waste hours on the wrong pressure washing solution. Find the SPITWATER pressure cleaner that matches your toughest cleaning challenges.

Contact a solutions specialist or your nearest dealer today and get the job done faster.

Comments