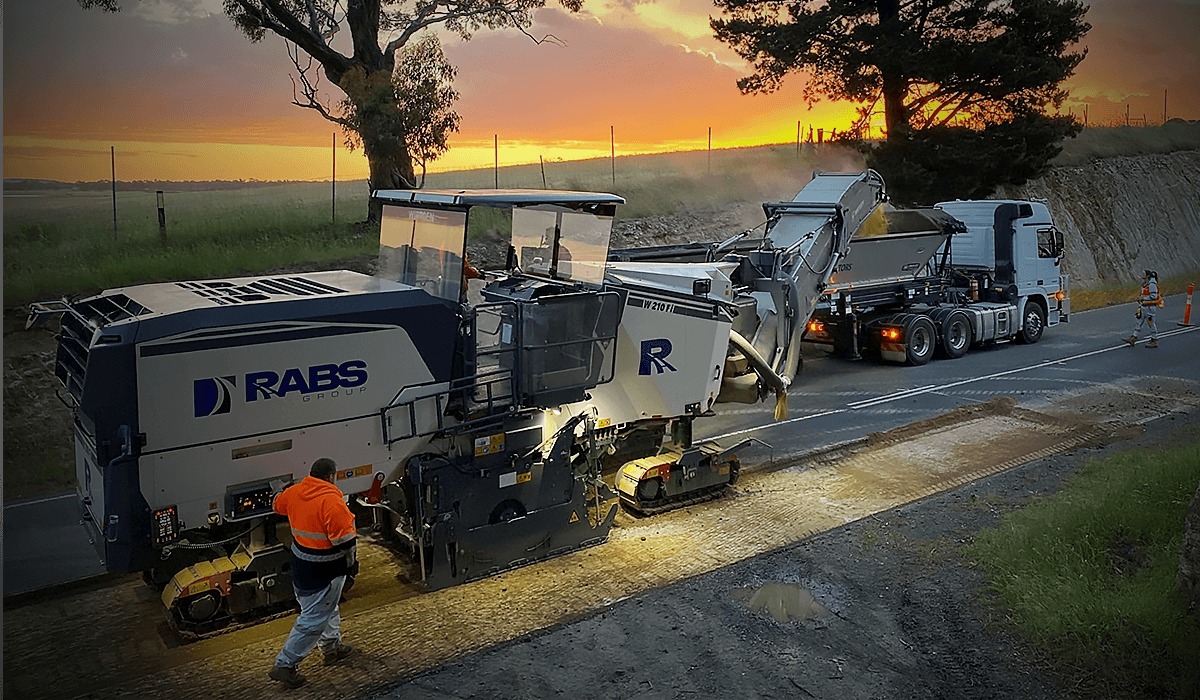

RABS Group delivers road and civil construction services across high-traffic urban environments. With an experienced team and fleet of specialist trucks and plant, most work is completed overnight to minimise public disruption and maximise safety.

The Problem

By early morning, trucks and plant return coated in road grime, dirt and bitumen tar, so cleaning has to happen fast.

Every minute spent washing vehicles ate into operator downtime, added to overtime costs and risked delaying the next shift.

RABS Group built a new wash pad and reached out to the Solution Specialists at SPITWATER to help with workflow and cleaning system design.

Three key needs were identified:

- The system had to be simple enough for multiple users to operate quickly.

- Bitumen tar, red dirt and built-up road grime needed serious water flow and chemical compatibility to remove effectively.

- Every aspect of the new wash bay needed to support quick turnaround and minimise operator fatigue.

The Solution

Following the detailed site assessment, the SPITWATER team designed a heavy-duty pressure cleaning setup that addressed the depot’s specific needs. The solution included:

- SPITWATER HP201S Pressure Cleaner: 21 LPM @ 3000 PSI make this machine ideal for fast, high-flow cleaning to remove sticky bitumen without damaging paintwork or decals.

- Foaming Bottle Attachment: Improves chemical cling and dwell time, increasing effectiveness of pre-wash degreasers and truck wash.

- External Hose Reel with 20m Hose: Mounted externally on the container for instant access. Operators can walk up, pull out the hose and get started in seconds.

- Dedicated Lance Storage: Keeps cleaning tools secure and organised for smooth shift transitions and safer walkways.

- Efficient Layout for Continuous Flow: The container placement, hose reel location and traffic flow were mapped to streamline the cleaning process - minimising crossover, reducing downtime and ensuring the wash bay supports multiple users at once without bottlenecks.

Container placement, hose reel location streamline the cleaning process.

The Results

- High water flow reduces reliance on brushes, cutting down the time needed to remove tar and grime from large surface areas.

- Operators finish sooner, reducing paid overtime and boosting depot efficiency during tight turnaround windows.

- The hose reel, lance storage and simple setup mean any team member can jump in and start cleaning without delays or special training.

- Keeping trucks and plant clean prevents tar staining and corrosion, extending equipment life and reinforcing the company’s reputation for professionalism.

- System layout improves workflow, reduces setup time and minimises clutter in shared spaces

Why It Works

The SPITWATER solution was built for RABS Group’s unique conditions - early morning use, tough contaminants, and a fast-paced depot environment.

The HP201S pressure cleaner, paired with smart accessories and a purpose-built install, delivered a system that’s tough on grime but easy on users.

Tough Cleaning. Smart Setup. Fast Results.

Together, this system gives the RABS team the power and simplicity they need to hit the ground running - day after day.

Not every job needs the same machine.

Speak to a SPITWATER Solutions Expert and get the right setup for your unique cleaning challenges.

Whether it’s stubborn grime, time pressure or compliance headaches—we’ll help you clean faster, smarter and without compromise.

Comments