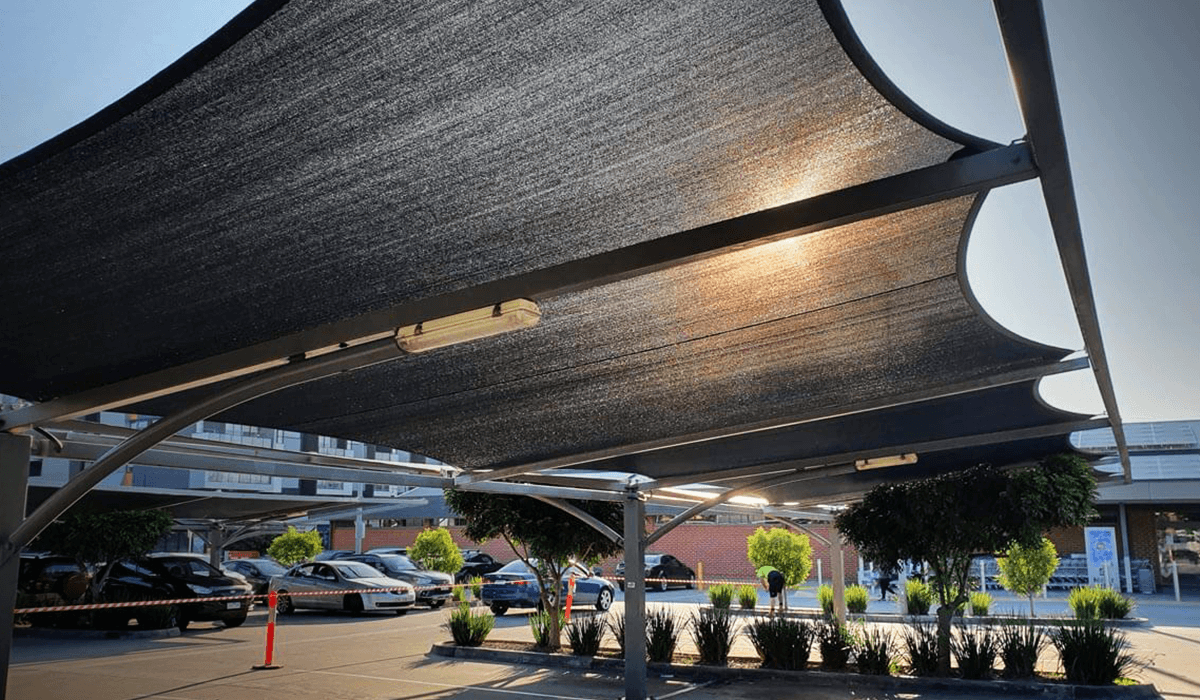

Shade Wise designs and installs high-quality shade sails that offer protection from Australia’s harsh sun. The team at SPITWATER helped create a fit for purpose cleaning system that protects and maintains UV effectiveness.

The Problem

Over time, exposure to dust, grime, and the elements can reduce both the visual appeal and UV effectiveness of shade sail installations.

Traditional cleaning methods were slow, labour-intensive and often inconsistent, leading to longer turnaround times and higher costs. some can be cleaned at site, but larger sails take time and may need to be taken down to be cleaned properly.

The Shade Wise team needed a reliable solution for deep-cleaning shade sails on-site and off-site. The equipment needed to be tough, easy to operate and gentle enough not to damage sensitive sail materials. Long-term, the goal for Shade Wise was clear; they wanted:

- A cleaning system that could extend the lifespan of each installation

- reduce post-installation service costs

- create a new revenue stream through professional cleaning and maintenance.

The Solution

To streamline the cleaning process, Shade Wise introduced a high-efficiency system powered by SPITWATER:

- HC12-180P Pressure Cleaner: Compact, powerful and portable. Perfect for on-site cleaning without the need for mains power.

- HP201S Pressure Cleaner: A high-flow cold water 21LPM unit built for bigger jobs, tackling heavy dirt, dust and grime fast.

- Rotowash Attachment: Used with the sails laid flat, the attachment provides a fabric-safe solution that’s fast, effective and repeatable.

Using this system, Shade Wise were able to:

- Lay out and clean shade sails flat, reducing strain on material stitching.

- Remove years of built-up dust and grime with minimal water and no harsh chemicals.

- Improve the effectiveness of the sail’s UV protection by removing surface contaminants.

The Results

SPITWATER’s solution helped Shade Wise transform their aftercare and maintenance offering.

The HP201S’s simple, electronics-free design makes it a dependable workhorse for onsite and workshop cleaning jobs. And with SPITWATER’s local servicing and spare parts network, they know help is always close if they need it.

Benefits at a glance:

- Time-saving performance for large-scale jobs

- Safe and effective for delicate fabrics

- No-fuss operation with rugged build and no electronics to fail

- Built reputation for excellent after-sales service and maintenance.

“Electronics and water don’t mix. The HP201S is the perfect match for what we do. It just works—and keeps working. We’re saving time, saving money and delivering better results for our customers.” - Shade Wise

Why It Worked

SPITWATER’s no-nonsense design and industrial-grade power made the HP201S and HC12-180P perfectly suited for Shade Wise’s cleaning needs.

Built for reliability in multi-user environments, both machines delivered consistent performance without the risk of electronics failing in wet conditions.

Combined with the Rotowash accessory, these machines provided a fabric-safe solution that’s fast, effective and repeatable—backed by local servicing and support that gives Shade Wise confidence long after the job’s done.

Tough Cleaning Made Easy

From schoolyards to commercial courtyards, SPITWATER makes light work of shade sail cleaning on site and off-site. Whether you're tackling dust, grime or UV build-up, our pressure cleaners are built for delicate surfaces, tough conditions and reliable results.

Not every job needs the same machine.

Speak to a SPITWATER Solutions Expert and get the right setup for your unique cleaning challenges.

Whether it’s stubborn grime, time pressure or compliance headaches—we’ll help you clean faster, smarter and without compromise.

Comments